FEEPOP Fire-resistance Cladding Board - 2440*1220*8-15mm

The FEEPOP Steel Structure Fireproof Cladding System is a passive fire protection solution designed to extend the time for steel beams and columns to reach critical temperatures during a fire. The system provides reliable fire protection while maintaining structural integrity, minimizing damage, and enhancing building safety.

It consists of FEEPOP fireproof boards, specialized coating materials, and supporting cladding frameworks, forming a complete fireproof solution for steel structural members. The system is available for steel beams (2.5h fire resistance) and steel columns (3h–4h fire resistance), meeting the GB 9978 fire resistance standards.

Product Highlights

Extended Fire Resistance

Effectively delays critical temperature rise in steel beams and columns, achieving 2.5h, 3h, or 4h fire ratings, ensuring safe evacuation and building protection.

Lightweight & Non-Destructive

Adds minimal weight to steel structures while providing high-performance fire protection.

Durable & Dimensionally Stable

Maintains coating integrity under long-term exposure, reducing cracking, spalling, or deformation during fire events.

Moisture & Mold Resistant

Reliable in humid indoor environments, resistant to mold growth, corrosion, and deterioration.

Fast Dry Installation

Dry construction method enables quick, clean installation, minimizing construction downtime and labor costs.

Eco-Friendly & Asbestos-Free

Safe for modern construction, free of harmful substances, compliant with green building standards.

Specifications

Dimensions: 2440*1220mm

Thickness: Available in 8-15mm

Material: Fiber Cement

Color: Grey

Application: Ideal for--Interior fire protection for steel beams and columns/ High fire-resistance zones in commercial and industrial buildings/ Public buildings, hospitals, schools, and data centers/ Buildings requiring compliance with GB 9978 fire resistance standards/ Any interior steel structure needing 2.5h–4h passive fire protection

Applications

Factory Overview | Feepop Manufacturing Base

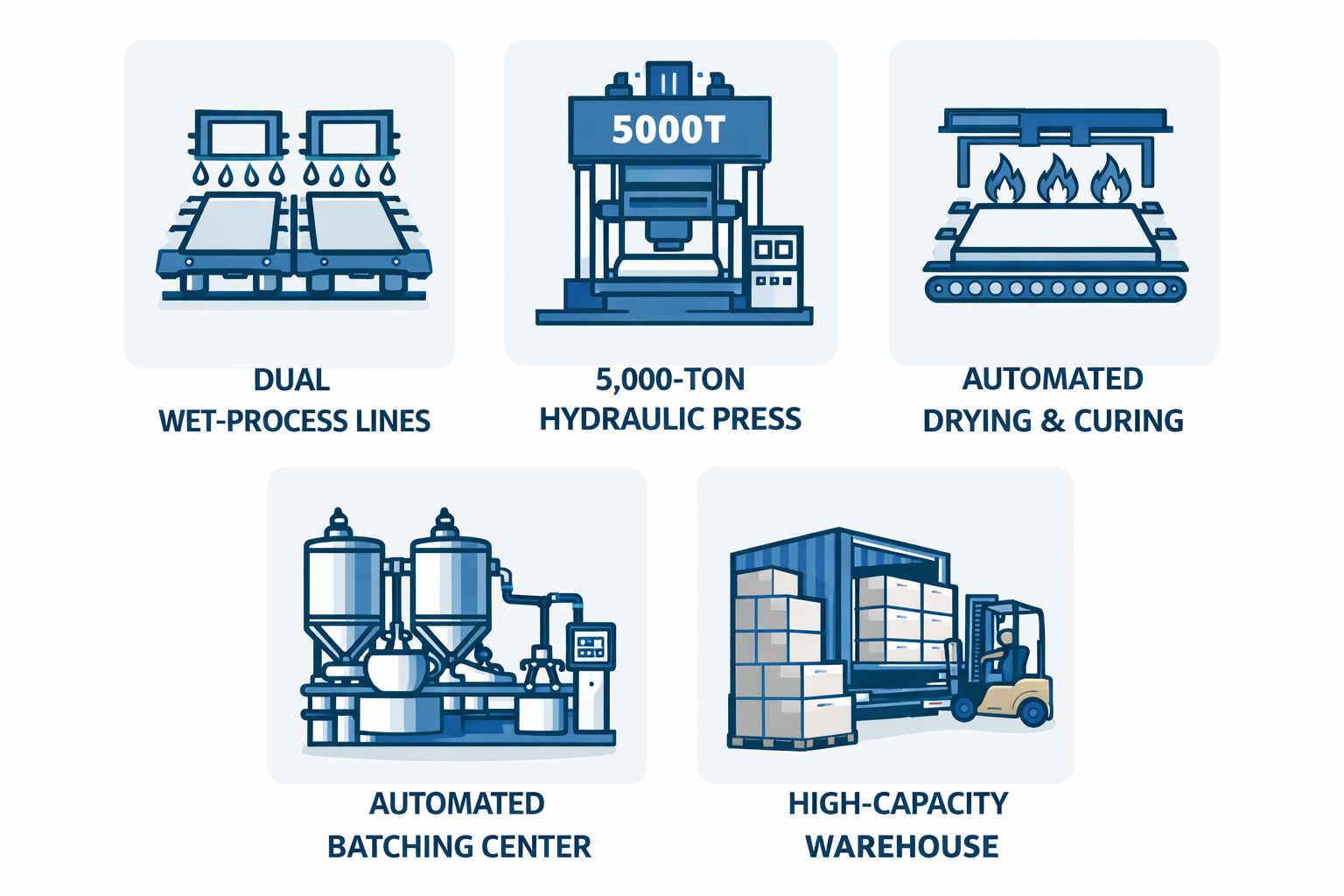

Guangxi Feepop Board Co., Ltd. operates a modern manufacturing facility covering approximately 20,700 m². The plant is equipped with two high-efficiency pulp-flow wet-process production lines, supported by automated batching systems, high-tonnage hydraulic presses, controlled-temperature drying systems, and automated stacking and packaging lines. This enables an annual production capacity of over 10 million m² of fiber cement and calcium silicate boards.

100% asbestos-free,

ISO9001,

SO14001,

ISO45001

lDual wet-process lines ensuring consistent density and stability.

l5,000-ton hydraulic press systems for improved strength and flatness.

lAutomated drying and curing systems reducing stress and deformation.

lAutomated raw-material batching center ensuring precise formulation.

lHigh-capacity warehouse supporting fast dispatch and container loading.

Feepop boards are engineered for humid, hot and coastal environments, offering moisture resistance, mold resistance, fire performance, dimensional stability and impact resistance. The manufacturing philosophy emphasizes:

lZero asbestos and zero harmful substances

lFull-process quality control from raw materials to final inspection

lEnvironmental production with recycling-water and dust-collection systems

lCompliance with international performance standards (SGS, CE, etc.)

Nanning Office | Headquarters Operations Center

The headquarters is located at Room 1136, Jinyuan CBD Plaza, No.63 Jinhu Road, Qingxiu District, Nanning, Guangxi. It functions as the company’s operational hub for domestic and international sales, customer service, technical support, export documentation and compliance, supply-chain coordination, major project management and after-sales service. The office and factory operate in an integrated system ensuring fast response and reliable delivery from inquiry to shipment.